How to Properly Flash Roof Pitch Transitions with Standing Seam Metal Roofs … “The Right Stuff”

December 29, 2016 | By Mike Gonet | Filed under: Articles, Education, Metal Roofing, Technical

Pitch Transitions Are a Common Roof Detail

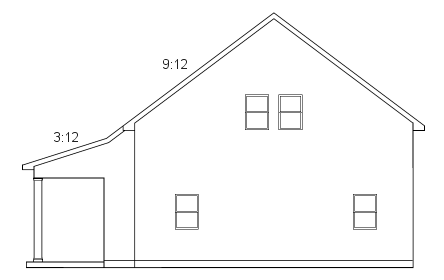

A roof pitch transition is a line in the roof plane that changes pitch. The roof plane goes from one pitch to a lower pitch. This is a fairly common roof detail. We see this quite frequently in Log Home roofs with porches, for example. See the illustration below.

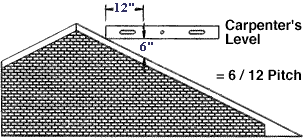

As you can see from illustration the roof changes pitch at the porch from a 9/12 to a 3/12 pitch. By the way, pitch is measured by picking any point on the roof, place a level on it, measure 12” out from that point (this is called the run) and then down to the roof surface from the bottom of the level (this is called the rise) to see how many inches the roof pitches over 12”.

Pitch Transition Points Can Be a Source of Problems

The transition point can be a source of problems if not done correctly. The transition has to be prepared properly with the right underlayments including high temperature ice and water shield when metal is being installed. Then a high quality synthetic underlayment should be installed as well.

Many times we will see a transition done by someone who just bends the metal panel to conform to the transition. See below.

A careful look will show this change in pitch was done haphazardly and shows a lack of metal roof installation knowledge. You can see that where the metal is bent and changing pitch. The metal is badly crimped and beginning to fail. The metal is cracking due to the movement of the metal and a poor installation. There is considerable oil canning, as well, for such short panels and there is no snow retention over the front door. This roof was installed only 8 years ago. How do we know this, you might ask? We gave this homeowner an estimate. He said our price was too high. We don’t think the owner was expecting this outcome. He got what he paid for…. a cheap metal roof.

Larger Roofs Can Lead to Larger Problems

The next picture shows that those problems can be multiplied when the roof is larger. Not only was the transition flashing not done, but the outcome was far worse due to the size of the roof. You can see the oil canning due to the stress on the panels and the inability of the panels to move freely because they were not terminated at the transition and properly flashed. Just plain UGLY! Definitely not “the right stuff.” We do not know which company was responsible for this roof.

Make Sure Your Roof Installer Has the “Right Stuff”

The next picture shown a log home with a classic transition change for the porch roof. You can see the transition flashing which separates the two roof planes at the pitch change. This flashing detail is important to maintain the integrity of the roof and it also helps to prevent oil canning as you can see from the picture. This roof was correctly done about 6 years ago by our own crew.

This roof was done with “the right stuff.” It is not just a metal roof. It is a Classic Metal Roof: “The best roof under the sun.”